- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

JSX335340LNG

![]()

1.The vehicle is used to transport liquefied natural gas (LNG) specially.Our company have been in this field several years. with the advantages of reasonable design, proven technology, safe and reliable. The design, manufacturing and inspection of our products are in accordance with the national standards: GB150, GB1589, it is equal to international standards. We can design different size tanks for users to correspond with local vehicles loaded weight standard.

2.Considering different countries have different road safety rules, defferent regulations, different road conditions. We’ll manufacture the tank semi trailer according to your sepecial situation.

![]()

| 526000L(52.6CBM) LNG Tank Trailer Specification | ||||

| Curb weight (Kg) | 19477 | Payload (Kg) | 20553 | |

| Total Weight (Kg) | 40000 | Dimension(mm)(L*W*H) | 13000*2500*3950mm | |

| capacity | 52600 L | Unit volume filling weight | 0.39(KG/L) | |

| Design temperature(°C) | -196 | Design pressure | 0.68mpa | |

| Applicable shipping medium | Liquefied natural gas(LNG) | Working pressure | 0.7mpa | |

| Inside tank material | 06Cr19Ni10 | Tank shell material | 16MnR/Q345R | |

| Adiabatic way | Vacuum \ multi-layer adiabatic | Adiabatic materials | Aluminum foil, adiabatic paper | |

| (Relief valve)opening pressure(Mpa) | 0.61 | |||

| 526000L(52.6CBM) LNG Tank Trailer Main configuration | ||||

| Items | Data | Items | Data | |

| (BPW 13T) | 3 set | Tire (12.00Triangle Vacuum) | 12 | |

| King pin | 1 set | Spare tire carrier | 1 set | |

| Steel mechanical suspension system | 1 set | Pneumatic brake system | 1 set | |

| 24V circuit system | 1 set | ABS | 1 set | |

| Loading and unloading valve | 1 set | loading and unloading hose | 1 set | |

| Content gauge (level gauge) | 1 set | Relief valve | 2 set | |

| Thermal meter | 1 set | Fire extinguisher | 2 unit | |

| Manometer | 1 set | Anti-static drag ground | 1 unit | |

| Cabinet | 1 unit | toolbox | 1 unit | |

Optional parts for the tanker semi trailer:

Axle quantity: 2 axle 3 axle 4 axle

Axle brand: FUWA / BPW and so on, 12ton, 13ton, 16ton, 18ton, 20ton.

Volume: 10 cube meters to 70 cube meters

Suspension: Air suspension, mechanic (leaf spring suspension), bogie suspension, etc.

Material: Carbon steel/aluminum/stainless steel material

Medidum: LNG and low tempreture liquid gas and so on

![]()

Plate rolling machine is applied for tank body,it is much faster and easier to control quality

The tank body sheet are welding together by the auto-welding machine to ensure the quality

Monoblock tank use less welding, which make the tank more steady and beautiful

Advanced sandblast, spray painting, purging, anti-corrosion procedure

Advanced mechanical property test, make sure the lowest shrinkage and the highest dimensional stability under low temperature

Strict NDT procedure. A&B welding joint perform 100%RT. C&D welding joint perform 100%MT

![]()

![]()

1.The vehicle is used to transport liquefied natural gas (LNG) specially.Our company have been in this field several years. with the advantages of reasonable design, proven technology, safe and reliable. The design, manufacturing and inspection of our products are in accordance with the national standards: GB150, GB1589, it is equal to international standards. We can design different size tanks for users to correspond with local vehicles loaded weight standard.

2.Considering different countries have different road safety rules, defferent regulations, different road conditions. We’ll manufacture the tank semi trailer according to your sepecial situation.

![]()

| 526000L(52.6CBM) LNG Tank Trailer Specification | ||||

| Curb weight (Kg) | 19477 | Payload (Kg) | 20553 | |

| Total Weight (Kg) | 40000 | Dimension(mm)(L*W*H) | 13000*2500*3950mm | |

| capacity | 52600 L | Unit volume filling weight | 0.39(KG/L) | |

| Design temperature(°C) | -196 | Design pressure | 0.68mpa | |

| Applicable shipping medium | Liquefied natural gas(LNG) | Working pressure | 0.7mpa | |

| Inside tank material | 06Cr19Ni10 | Tank shell material | 16MnR/Q345R | |

| Adiabatic way | Vacuum \ multi-layer adiabatic | Adiabatic materials | Aluminum foil, adiabatic paper | |

| (Relief valve)opening pressure(Mpa) | 0.61 | |||

| 526000L(52.6CBM) LNG Tank Trailer Main configuration | ||||

| Items | Data | Items | Data | |

| (BPW 13T) | 3 set | Tire (12.00Triangle Vacuum) | 12 | |

| King pin | 1 set | Spare tire carrier | 1 set | |

| Steel mechanical suspension system | 1 set | Pneumatic brake system | 1 set | |

| 24V circuit system | 1 set | ABS | 1 set | |

| Loading and unloading valve | 1 set | loading and unloading hose | 1 set | |

| Content gauge (level gauge) | 1 set | Relief valve | 2 set | |

| Thermal meter | 1 set | Fire extinguisher | 2 unit | |

| Manometer | 1 set | Anti-static drag ground | 1 unit | |

| Cabinet | 1 unit | toolbox | 1 unit | |

Optional parts for the tanker semi trailer:

Axle quantity: 2 axle 3 axle 4 axle

Axle brand: FUWA / BPW and so on, 12ton, 13ton, 16ton, 18ton, 20ton.

Volume: 10 cube meters to 70 cube meters

Suspension: Air suspension, mechanic (leaf spring suspension), bogie suspension, etc.

Material: Carbon steel/aluminum/stainless steel material

Medidum: LNG and low tempreture liquid gas and so on

![]()

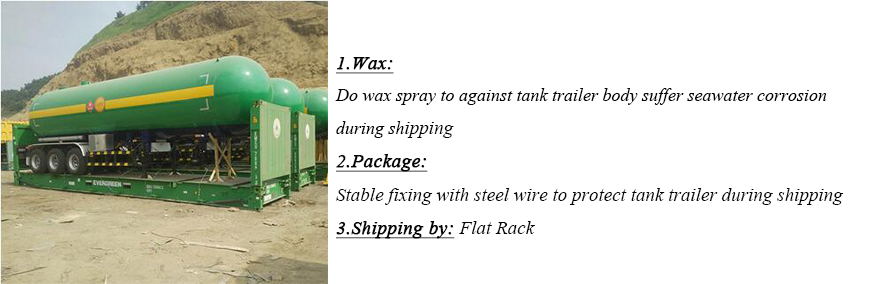

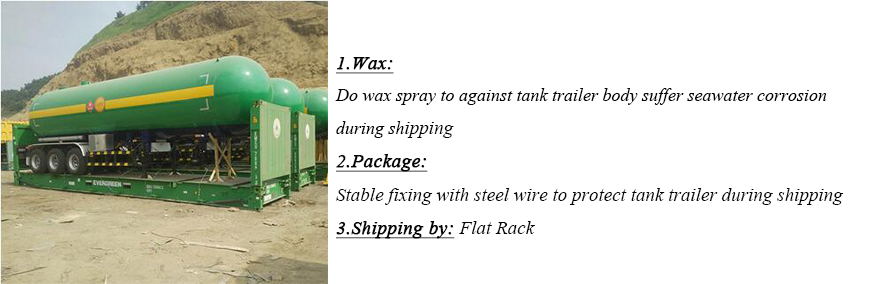

Plate rolling machine is applied for tank body,it is much faster and easier to control quality

The tank body sheet are welding together by the auto-welding machine to ensure the quality

Monoblock tank use less welding, which make the tank more steady and beautiful

Advanced sandblast, spray painting, purging, anti-corrosion procedure

Advanced mechanical property test, make sure the lowest shrinkage and the highest dimensional stability under low temperature

Strict NDT procedure. A&B welding joint perform 100%RT. C&D welding joint perform 100%MT

![]()