- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

JSX334520LPG

12900*2500*3980(mm)

20Tons - 22Tons

![]()

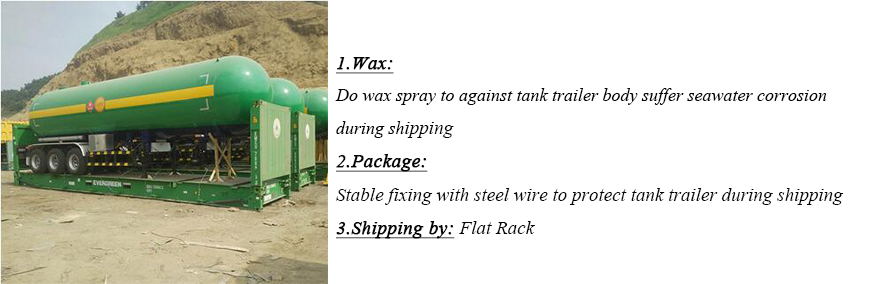

1.LPG gas tank semi trailer, mainly used for transport Liquefied Petroleum Gas, In addition, It can also transport other gas.Such as: propane, propylene, liquid ammonia, dimethyl ether and methanol, butadiene, isobutane, epoxy ethane,methyl amine in different properties, such low pressure liquefied gas under normal temperature.

2.Considering different countries have different road safety rules, defferent regulations, different road conditions. We’ll manufacture the tank semi trailer according to your sepecial situation.

![]()

![]()

| Wheelbase | 6800+1310+1310(mm) | Tyres No | 12+1Pcs | ||

| Rear track | 1840/1840/1840(mm) | Tyre type | 12 tubeless | ||

| Total mass | 40T | Tyre carrier | 2 spare tyre carrier | ||

| Size | 12900*2500*3980(mm) | Frame | Carbon steel | ||

| Curb weight | 16.48T | King ping | #50 | ||

| Loading mass | 20T to 22T | Brakes | yes | ||

| Steel spring NO | -/7/7/7 | Dust guard | dust guard of rubber | ||

| Axles brand | FUWA or BPW | Tanker volume | 56000L | ||

| Axles NO | 3Pcs | Tanker material | Carbon steel Q345R | ||

| Axles loading | 13000kg | Tanker thickness | 15mm | ||

| Legs brand | Jost | Tanker diameter | 2450mm | ||

| Legs loading | 28000kg | Tanker design pressure | 2Mpa | ||

![]()

Plate rolling machine is applied for tank body,it is much faster and easier to control quality

The tank body sheet are welding together by the auto-welding machine to ensure the quality

Monoblock tank use less welding, which make the tank more steady and beautiful

Advanced sandblast, spray painting, purging, anti-corrosion procedure

Advanced mechanical property test, make sure the lowest shrinkage and the highest dimensional stability under low temperature

Strict NDT procedure. A&B welding joint perform 100%RT. C&D welding joint perform 100%MT

![]()

![]()

1.LPG gas tank semi trailer, mainly used for transport Liquefied Petroleum Gas, In addition, It can also transport other gas.Such as: propane, propylene, liquid ammonia, dimethyl ether and methanol, butadiene, isobutane, epoxy ethane,methyl amine in different properties, such low pressure liquefied gas under normal temperature.

2.Considering different countries have different road safety rules, defferent regulations, different road conditions. We’ll manufacture the tank semi trailer according to your sepecial situation.

![]()

![]()

| Wheelbase | 6800+1310+1310(mm) | Tyres No | 12+1Pcs | ||

| Rear track | 1840/1840/1840(mm) | Tyre type | 12 tubeless | ||

| Total mass | 40T | Tyre carrier | 2 spare tyre carrier | ||

| Size | 12900*2500*3980(mm) | Frame | Carbon steel | ||

| Curb weight | 16.48T | King ping | #50 | ||

| Loading mass | 20T to 22T | Brakes | yes | ||

| Steel spring NO | -/7/7/7 | Dust guard | dust guard of rubber | ||

| Axles brand | FUWA or BPW | Tanker volume | 56000L | ||

| Axles NO | 3Pcs | Tanker material | Carbon steel Q345R | ||

| Axles loading | 13000kg | Tanker thickness | 15mm | ||

| Legs brand | Jost | Tanker diameter | 2450mm | ||

| Legs loading | 28000kg | Tanker design pressure | 2Mpa | ||

![]()

Plate rolling machine is applied for tank body,it is much faster and easier to control quality

The tank body sheet are welding together by the auto-welding machine to ensure the quality

Monoblock tank use less welding, which make the tank more steady and beautiful

Advanced sandblast, spray painting, purging, anti-corrosion procedure

Advanced mechanical property test, make sure the lowest shrinkage and the highest dimensional stability under low temperature

Strict NDT procedure. A&B welding joint perform 100%RT. C&D welding joint perform 100%MT

![]()